Since September 2019 the experiment on the labeling of cigarettes lasted.

Since January 1, 2021, only labeled products (filtered cigarettes) are produced and imported.

Beginning July 1, 2021, manufacturers will ship only labeled products to the wholesaler;

Beginning October 1, 2021, distributors will ship only labeled products to the retail tier;

Beginning January 1, 2022, sales of unlabeled cigarettes will be prohibited throughout Uzbekistan.

From October 1, 2022, mandatory labeling will be introduced for all types of tobacco products, including heating tobacco.

Tabakindustrie (Uzbekistan)

Tabakindustrie (Uzbekistan)

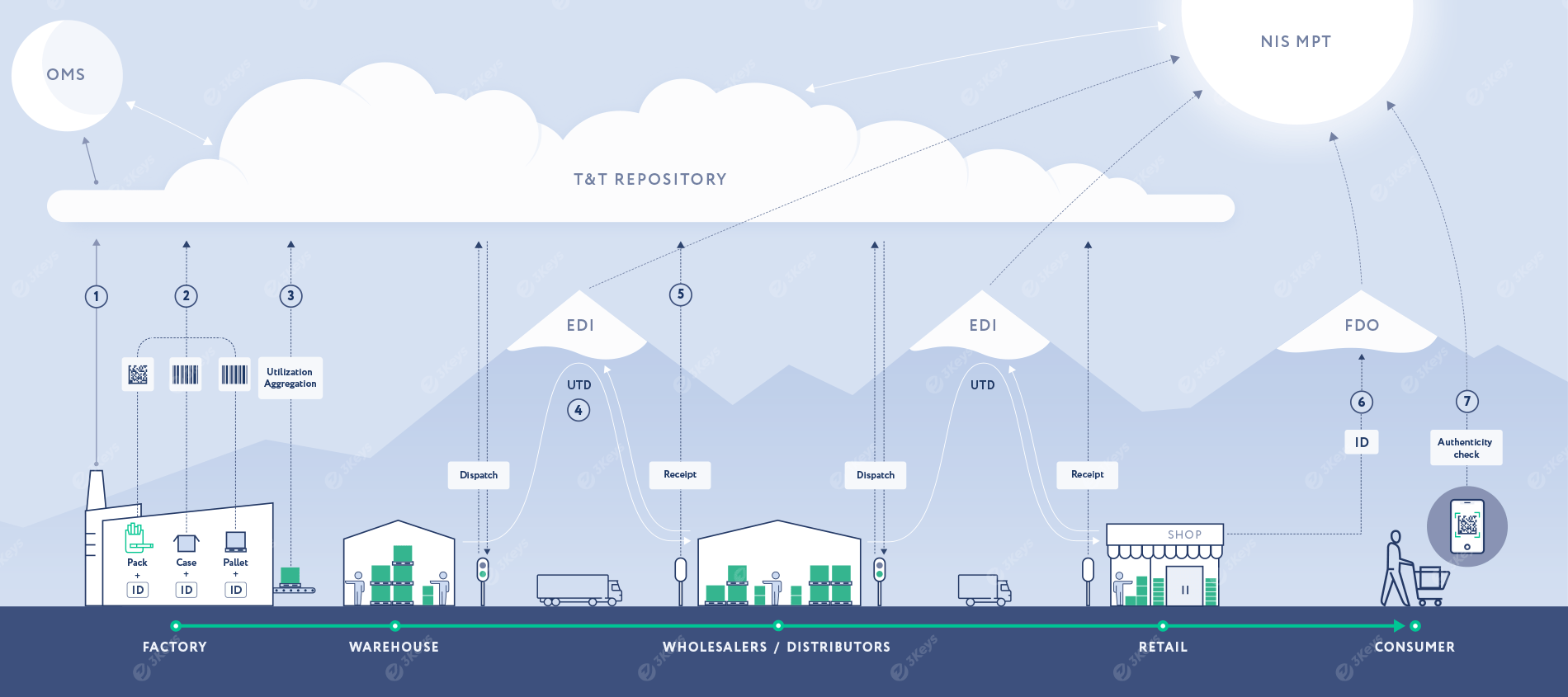

Uzbekistan Track&Trace regulations for the tobacco industry

The manufacturer orders unique serial numbers with crypto codes for each trade item in accordance with the production plan to order management system (OMS).

In case of a direct printing scenario, these serial numbers are passed to manufacturing facilities, where they are encoded into Data Matrix codes and applied to individual consumer packages during production. The packages are placed into cases and other forms of containers and are then further aggregated into pallets. Each level of the container is labeled with a unique SSCC of GS1-128 codes assigned by the manufacturer. Codes are associated with a parent/child structure.

Each hierarchically structured serialization code is stored in a private repository and transmitted to OMS with additional attributes, such as expiration date. After the end of the production of a batch and the quality control procedure, the serialized packages are reported to NIS MPT as being available for further sale.

Each serialized package is scanned and the unique codes are transmitted to the ESF operator. NIS MPT receives information from the ESF operator about a change of ownership for these codes.

While receiving a serialized shipment, the wholesaler scans serialized shipping unit or package to verify upon inbound ESF. A change of ownership occurs when the ESF is signed. Then ownership information is pushed to NIS MPT from the ESF operator automatically.

Finally, when the serialized package is sold at a retail store to the end-consumer, the Data Matrix is scanned. The unique serial numbers are included in the electronic cash receipt, which is sent via a Fiscal Data Operator to NIS MPT.

Any consumer can scan a Data Matrix code with a phone app ASL Belgisi to verify the authenticity of the product and learn more about its origin.

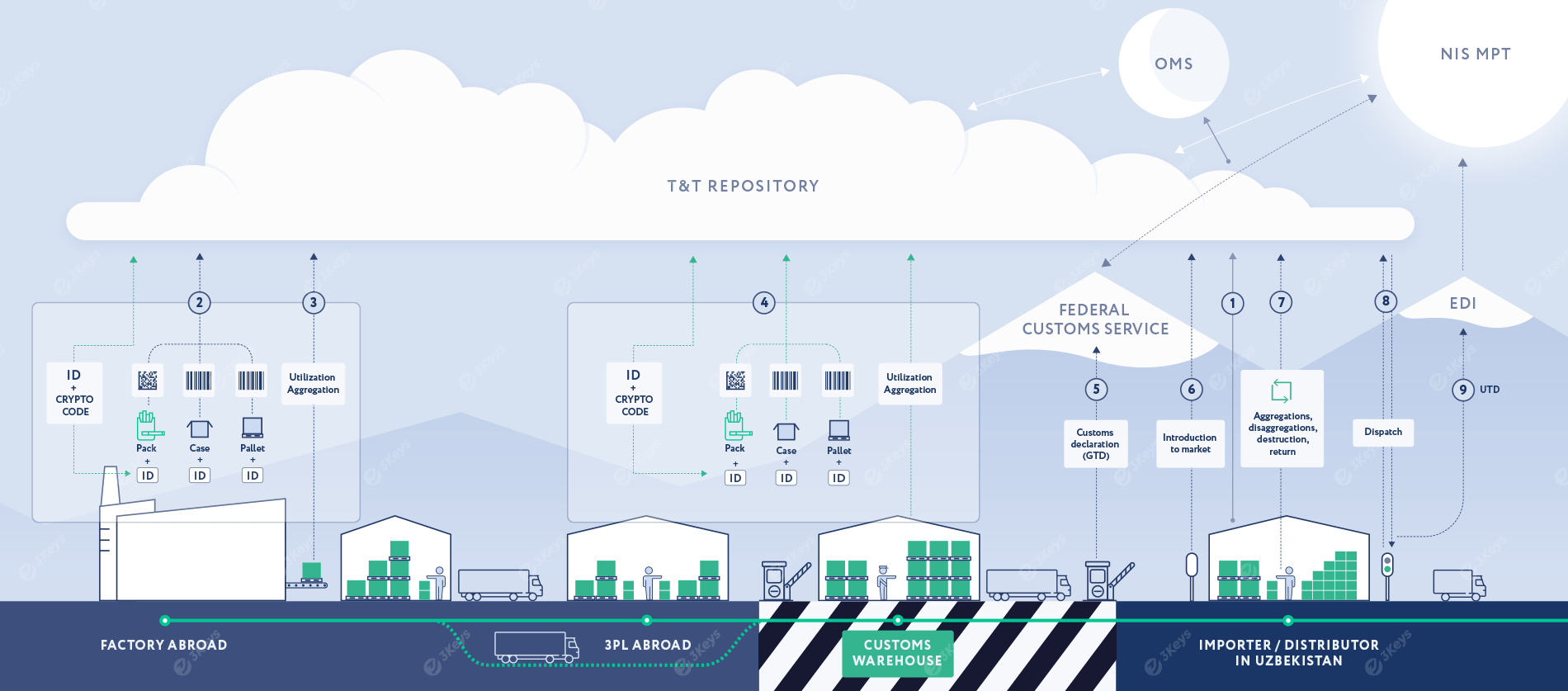

Uzbekistan Track&Trace regulations for the importing tobacco

The importer orders unique serial numbers with crypto codes for each produced trade item based on the production/purchase plan. The serial numbers and crypto codes are emitted by the OMS system. Then, the ordered serial numbers are transferred to the manufacturer for products serialization.

In case of a direct printing scenario, these serial numbers are passed to manufacturing facilities, where they are encoded into Data Matrix codes and applied to individual consumer packages during production. The packages are placed into cases and other forms of containers and are then further aggregated into pallets. Each level of the container is labeled with a unique SSCC of GS1-128 codes assigned by the manufacturer. Codes are associated with a parent/child structure.

Each hierarchically structured serialization code is stored in a private repository and transmitted to OMS with additional attributes, such as expiration date.

Alternatively, the serialization process can take place at a warehouse outside Uzbekistan or at the customs warehouse. The full hierarchy has to be reported to NIS MPT before the shipment can be customs-cleared.

The importer or the customs broker submits a customs declaration (GTD) to the State Customs Committee of the Republic of Uzbekistan. Which clears the shipment and allows its import into Uzbekistan.

After customs control, the importer submits a Market Release Report to the NIS MPT, which is the entry of the serialized goods into circulation.

At any given point in the supply chain, product aggregation can be changed. When this happens, it is reflected in the repository and reported to NIS MPT. Likewise, products can be written off for various reasons, such as damages, expiration, or shortages.

Serialized goods in shipping packages and on pallets are sent by the manufacturer to the next partner in the supply chain.

Each serialized package is scanned and the unique codes are transmitted to the ESF operator. NIS IPT receives information from the ESF operator about a change of ownership for these codes.