1 April 2020 – 1 June 2021—Pilot project for labeling packaged water

1 September 2021—the start of mandatory registration in the Chestny Znak/CRPT serialisation system.

Manufacturers, importers, wholesalers, and retailers that sell packaged water on 2021 September 1 or within seven days of the date of the need to sell packaged water must submit an application for registration in the Chestny Znak/CRPT serialisation system.

2021 December 1—mandatory serialisation for mineral water

Starting from 2021 December 1, serialisation will become mandatory for mineral water.* Mineral water manufacturers and importers must be registered in the Chestny Znak system and describe their products in the Nacionalnyy Catalog. By this time, the processes for ordering and payment for codes, as well as code application on the package and introduction to the market, including reporting, should be fully implemented. The turnover of non-serialised mineral water will become illegal on 2021 December 1.

1 March 2022—mandatory serialisation for other categories of packaged drinking water

By March 2022, manufacturers and importers of any packaged drinking water** must be registered in the Chestny Znak system and describe their products in the Nacionalnyy Catalog. By this time, the processes for ordering and payment for codes, as well as code application on the package and introduction to the market, including reporting, should be fully implemented. The turnover of non-serialised drinking water will become illegal on 2022 March 1.

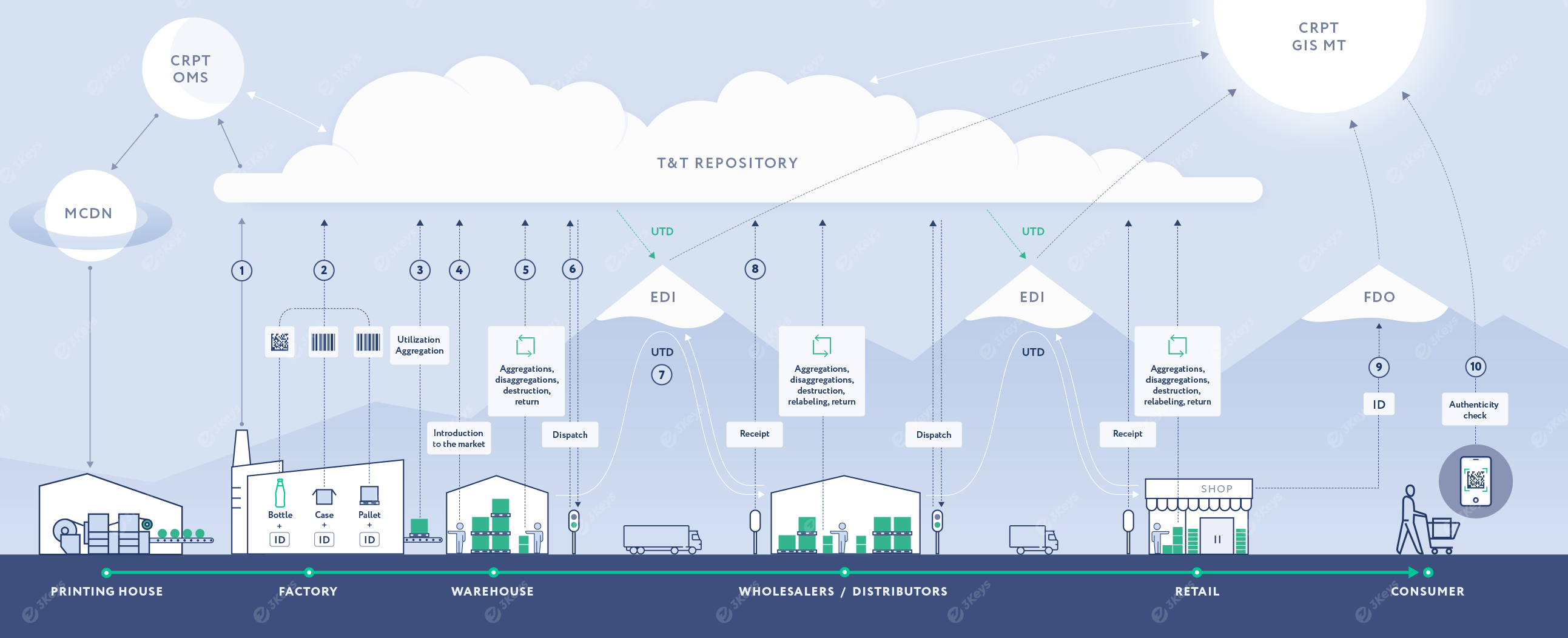

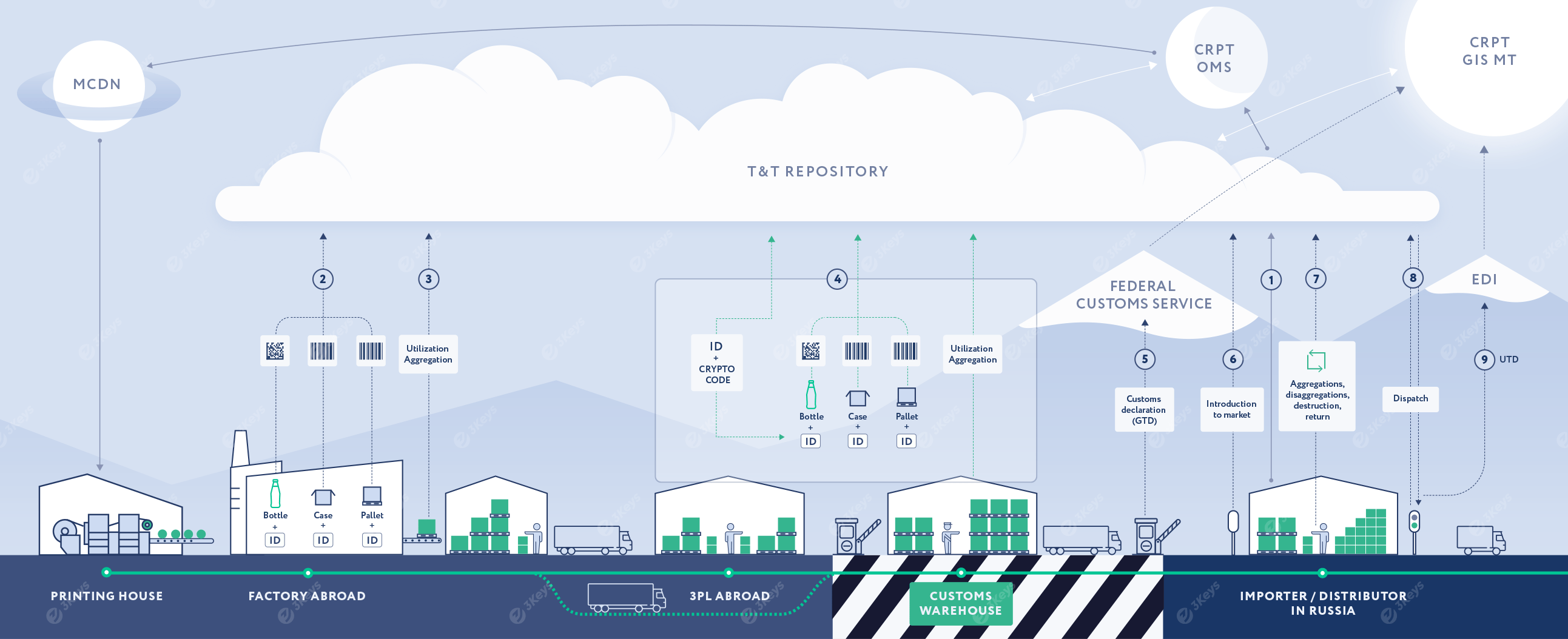

1 November 2022—mandatory volume and article reporting on the turnover of serialised packaged water

Manufacturers, importers, wholesalers, and retailers need to use electronic document flow when dispatching and receiving goods. Participants should choose an EDI operator and implement, configure, and test electronic document flow with other parties. It must report information about batches of goods to the marking system (the product code and the quantity of the marked goods to be shipped) without specifying the codes that are being moved between them.

From March 1, 2023 – There is an obligation to transfer information to the labeling system on the retail sale of labeled water for all participants in the turnover.

All participants selling any types of packaged water must start scanning codes and report sales information to the system via cash registers. By this time, sales processes must be tested, 2D scanners must be available at cash registers, and cash register software should be upgraded if necessary

From December 1, 2023 – It becomes mandatory to transfer information to the labeling system on the disposal of packaged water for the HoReCa segment and government agencies.

Participants of the turnover in HoReCa segment (restaurants, cafes, hotels) and government agencies (canteens at schools, kindergartens and hospitals), purchasing packagesed water for not selling purposes, must report the disposal of packaged water to the monitoring system. Participants should choose an EDI operator and implement, configure, and test electronic document flow with other parties.

1 March 2025—item reporting on the turnover of serialised packaged water

Manufacturers, importers, wholesalers, and retailers need to use electronic document flow when dispatching and receiving goods. Participants should choose an EDI operator and implement, configure, and test electronic document flow with other parties. It must report information about each serialised item to Chestny Znak/CRPT.

* products with HS codes 2201, including 2201 10, OKPD 2 11.07.11.110

** products with HS codes 2201, including 2201 90 000 0, OKPD 2 11.07.11.120, 11.07.11.130, 11.07.11.140